FCM CAT.CAE-Bridge

FCM CAT.CAE-Bridge: Seamlessly Connect CAD and CAE

Quickly and robustly generates parameterized CATIA V5 design variants for the simulation process

Direct use of a CAD model for simulations is a time-consuming hurdle. There is a lack of end-to-end processes that can be applied by non-experts, as well as stable, highly parametric geometry descriptions to enable widespread use of simulation.

The FCM CAT.CAE-Bridge offers a comprehensive solution to overcome this challenge. It allows simulations to be fully automated and initiated directly from CATIA V5. These simulations can be integrated into a closed loop to perform variant studies with more powerful parameters and optimizations. This completely eliminates the need for the usual post-processing in CAD after the CAE simulation.

Boosting Efficiency with the FCM CAT.CAE-Bridge

100% update stability in CAD

90% time savings through fully automated variant creation

100% of the solution space is considered

Benefits of the FCM CAT.CAE-Bridge

- Significant time savings and reduced error rates due to improved design quality

- Streamlined product development process

- Large shape changes directly from the CATIA V5 geometry

- Joining techniques automatically adapt

- No geometry rework needed after functional shape changes from simulation

Efficient Variant Generation in CATIA V5

With the FCM CAT.CAE-Bridge, design variants can be quickly and reliably generated directly in CATIA V5. These variants can then be evaluated in a simulation process, allowing simulations to be run directly from the geometry. The result is a structure with improved properties.

Informed Decision-Making in Product Development

The evaluation of design ideas and concepts enables informed decision-making throughout all stages of product development. Not only can the components themselves or their positions relative to each other be altered, but the connections between components can also be assessed.

High Accuracy in Shape Changes

The FCM CAT.CAE-Bridge ensures the maintenance of precise tolerances, such as gap dimensions between different components. These boundary conditions are taken into account when generating variants.

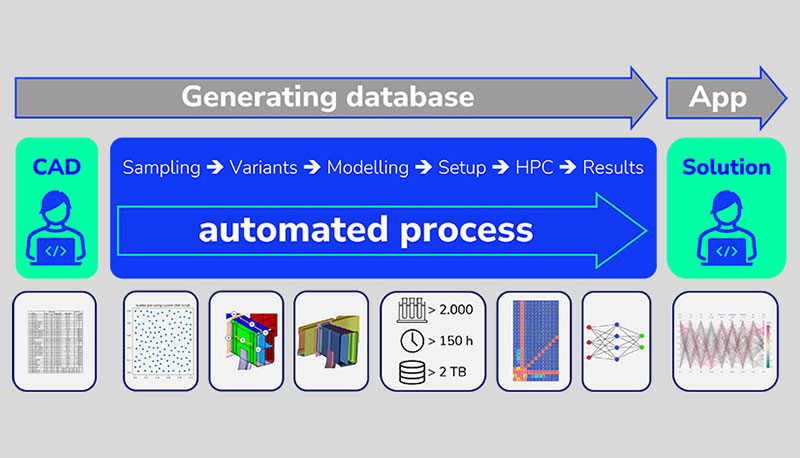

Automation of Simulation Models

Creating thousands of design and simulation models for machine learning (ML) is a major challenge without automation. The FCM CAT.CAE-Bridge automates all process steps and efficiently integrates parameters, dependencies, and joining techniques into CAD models. This saves time and lays the foundation for powerful ML-based applications.

FCM CAT.CAE-Bridge

Proof of Concept

Steps of the Proof of Concept

1. Introduction Workshop

- Presentation of the features of the FCM CAT.CAE-Bridge in relation to the component

- Selection of a component and definition of geometric variability (build space, shape and topology changes, rib structure, cutouts, flanges, etc.)

- Definition of the timeline, contacts, approach, and focus areas of the PoC

2. Design

- Through screen sharing, we will demonstrate the principles of the technology, best practices, and how the component design can be carried out using the features of the FCM CAT.CAE-Bridge. (2 days)

3. CAE Workshop

- Presentation of the CAE process chain using an existing example and discussion of simulation options.

- Evaluation of the opportunities and limitations of using simulation.

4. Practical Application

- Installation of the FCM CAT.CAE-Bridge in your existing and complete CATIA V5 environment*.

- Support for your design activities through regular meetings (2x1h per week over 3 weeks)

5. Closing Meeting

- Joint feedback from the testing phase and next steps

Price: 9,950 €

*We will share the requirements with you during the introduction workshop or upon request.

FAQ

▼ 1. What is the FCM CAT.CAE-Bridge?

The FCM CAT.CAE-Bridge is an extension for CATIA V5. The software is easy to install as a plug-in and generates fully simulation-capable CATIA V5 models. These models are fully and robustly parameterized by the FCM CAT.CAE-Bridge, allowing for the derivation of many valid versions of the design that can be evaluated through simulation.

▼ 2. How does the FCM CAT.CAE-Bridge interact with other software?

As a CATIA plugin, the FCM CAT.CAE-Bridge always requires CATIA V5. For generating various variants, an optimizer is used (OpenSource or commercial products such as OPTIMUS). A complete simulation process chain is required for the subsequent simulation process. The created CATIA models are passed to a preprocessor. The FCM CAT.CAE-Bridge works particularly well with Ansa and Hypermesh. A CAE solver is also needed (e.g., Nastran, Abaqus, LS-Dyna). The results are then processed and evaluated in a postprocessor (e.g., MetaPost or Animator).

▼ 3. What are the benefits of the FCM CAT.CAE-Bridge?

Speed:

- High automation of the entire process chain

- The geometry reversion from the design process is eliminated, and the optimized result is immediately available

Best Products:

- The robust parametrization utilizes the entire available design space for the optimal result

Maximum Flexibility:

The parametrization allows for:

- Turning parts of the design on/off, such as bulkheads

- Varying the number and placement of ribs and holes

- Modifying component connections (weld points, adhesive seams, flange sizes, distances, etc.)

Robustness:

- The stable parametrization and integrated variant tester enable the derivation of model variants

▼ 4. Who uses the FCM CAT.CAE-Bridge?

Designers use the FCM CAT.CAE-Bridge in CATIA V5 to generate the variant space for the subsequent simulation process through parametric design, which is carried out by calculation engineers. The simulation process itself is fully automated and directly derives variants from CATIA.

▼ 5. What are the software and hardware requirements for working with the FCM CAT.CAE-Bridge?

- Software: For the currently supported versions V5R21-32, the CATIA V5 modules HDA and KT1 (product knowledge template) must be installed.

- Hardware: The FCM CAT.CAE-Bridge and CATIA V5 require the same hardware specifications. Any workstation running CATIA V5 is also suitable for the FCM CAT.CAE-Bridge. Disk space required for installation ranges from 100MB to 1GB, depending on the scope.